Leading Heat Exchanger Manufacturer in India - An Heat Exchanger is an important part of any Equipment, that produces waste heat like generator, engine and power pack. So There are many types of Heat Exchangers are required as per the specific necessity of the equipment. For instance, there are many types of Heat Exchangers are available in the market. Some of them include shell and tube heat exchanger, industrial heat exchanger, mild steel heat exchanger, air cooled heat exchanger, injection moulding, and brazed plate heat exchanger, etc.

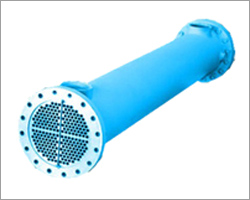

Our Company Swastik Hydraulic is one of the best heat exchanger manufacturers in India, Delhi. We offer shell and tube type of industrial heat exchanger in Delhi NCR. shell and tube heat exchanger is a simple, but effective type of heat exchanger. This type of heat exchanger comprises a cylinder shell which contains a bundle of tubes. In most of applications, hot fluid flows outside the tube and coolant flows through tubes and transfer the heat between thermally conductive material used in the heat exchanger.

Yes, we also have options for customization depending on the need of the customer in terms of size, capacity as well as the kind of material wanted. This is because our engineering group focuses closely on customers to achieve the best engineering results.

All our heat exchangers are produced with quality controls in accordance with industrial standards to achieve efficient and safe performance.

This is because you can easily seek a quote by either using the website or making a call on the phone. Kindly, elaborate on some of the aspects that need the due response as soon as possible.

Yes, it is possible to change the size, material and design of heat exchangers and deliver it according to the customer's requirements.

Yes, we have adequate customer service support after sales to help the customers maintain the products and also to provide a solution in case of any problem.

Shell and Tube heat exchangers can be categorized as high efficiency and high reliability and they can be used in high-pressure applications systems. They are also flexible and can also be easily managed.